Buildings in the institutional and industrial sector benefit from submetering as they often lack accurate and reliable metering data.

Military bases, universities, colleges and factories typically only have main utility meters installed to capture the consumption for an entire facility or the larger buildings within a complex. This leads to insufficient or inaccurate performance analysis, incorrect utility cost allocation and reduced ability to control their consumption. Tracking consumption and trends within a building enables facility managers to make informed decisions about their properties, such as potential equipment replacement or upgrades, as well as reducing their carbon footprint.

Track Consumption to Make Informed Decisions

In his paper “Conducting a metering assessment to identify submetering needs at a manufacturing facility”, Prakash Rao found that submetering was essential to track power usage in manufacturing facilities.

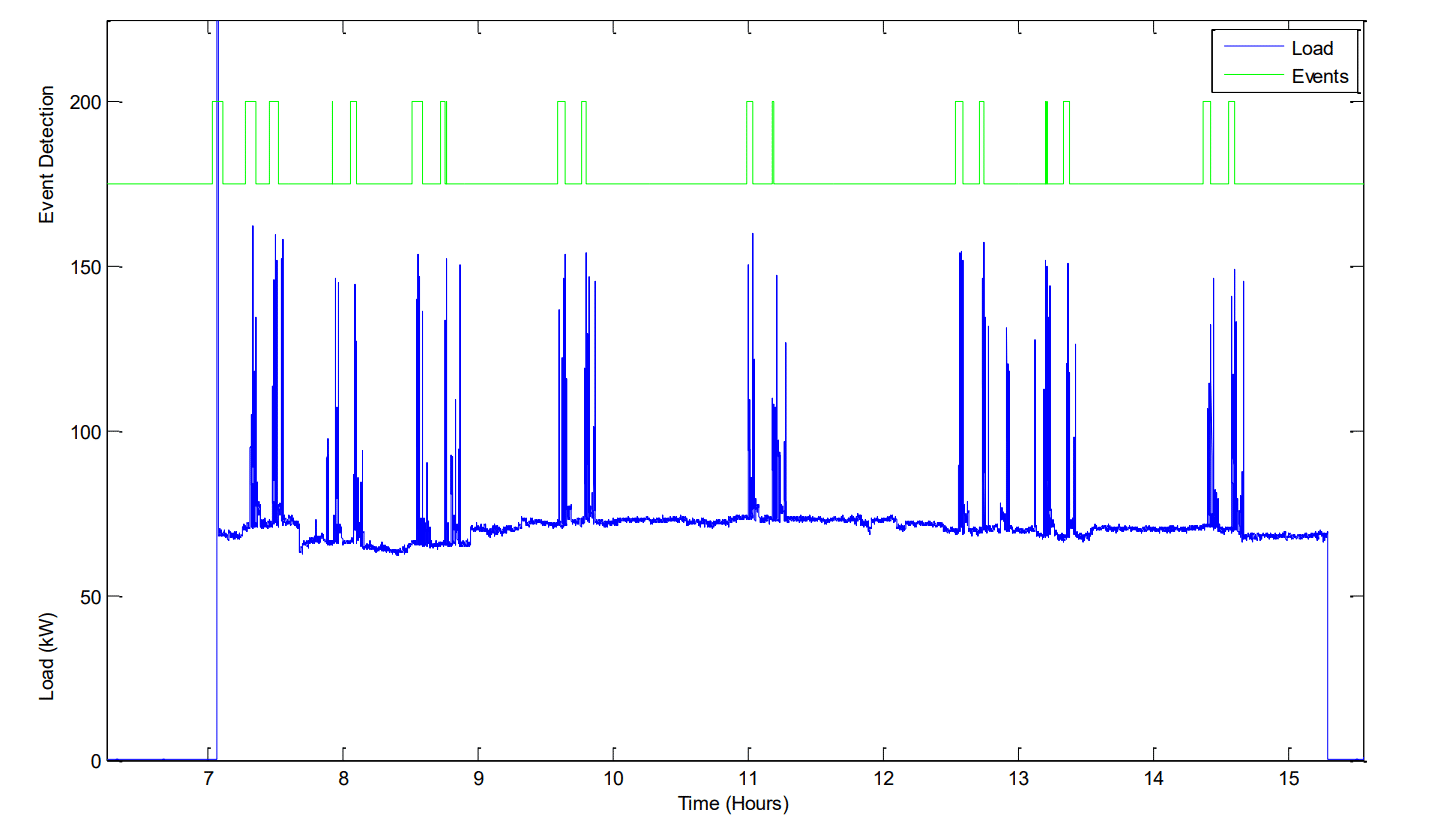

Prakash describes a metal manufacturer that wanted to understand what part of their factory was drawing the most electricity and at what times. The company performed a baseline audit of their machines and then had temporary submetering installed. This allowed them to verify the accuracy of the existing system as well as identify unnecessary run times on machines.

After comparing the metering data with their previous energy bills, the metal manufacturer realized that machines should be turned off if they had an idle time higher than two minutes and 34 seconds.

If the company had identified this in the three months leading up to the temporary submetering installation they would have saved 140 hours of run time on just one machine without sacrificing productivity and would have greatly reduced their carbon footprint in the process in a short time period. For instance, if the average load was 65 kW, this would mean the manufacturer would have saved 9,100 kWh of energy, or around 6.4 tons of CO2 (based on EPA estimates).

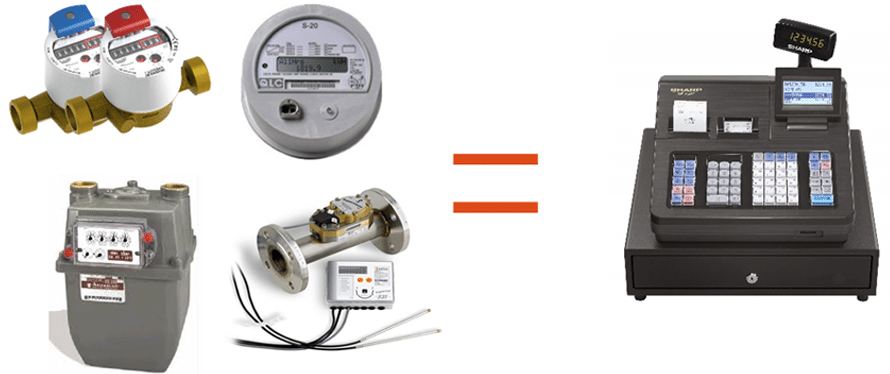

Your Submetering System Is Your Cash Register

A submetering system allowed the metal manufacturer to make an informed decision to reduce and conserve their utility use. Much like a cash register, a submetering system can keep detailed information on what comes in and goes out, allowing you to track the utility usage for your building.

Having accurate historical consumption data is the first step to estimating potential savings for retrofits in the future.

QMC offers energy audits, temporary submetering installations and more for your institutional or industrial facility. To learn more about how we can help your new or existing site, contact us today.

Read more